Trends and developments in automation equipment: leading the future innovation of the sheet metal processing industry

Under the wave of intelligent transformation of the global manufacturing industry, automation equipment is becoming the core engine to promote the high-quality development of the sheet metal processing industry.

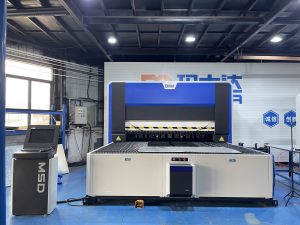

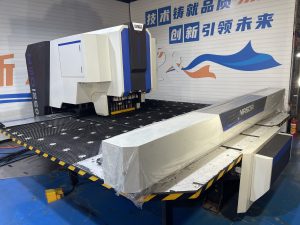

As a manufacturer focusing on the research and development of bending machines, CNC punching machines and sheet metal composite machines, Masda has always been driven by technological innovation to help global customers achieve double breakthroughs in efficiency and precision in sheet metal processing fields such as door industry, fire protection facilities, kitchen cabinets, etc.

1. Deep integration of intelligence and digitalization

In the era of Industry 4.0, the Internet of Things (IoT), artificial intelligence (AI) and big data technologies are accelerating their penetration into the production process.

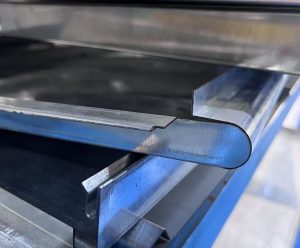

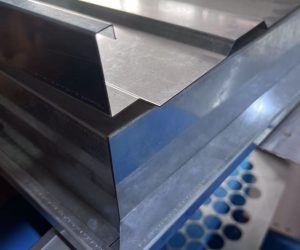

Intelligent CNC systems can significantly improve equipment accuracy (error can be controlled within ±0.05mm) through real-time data monitoring and adaptive adjustment.

2. The demand for flexible production has surged

The rise of multi-variety and large-volume orders has driven the development of equipment towards modular and reconfigurable design.

By integrating robotic arms and automated logistics systems, Masda’s bending machines can achieve fast mold change (mold change time is reduced by 70%), be compatible with a variety of materials and process requirements, and meet the flexible production of fire protection facilities, kitchen utensils and other diversified scenarios.

3. Green manufacturing and energy saving and efficiency improvement

Global environmental protection policies are becoming stricter, and greening has become an irreversible trend.

Automation equipment achieves sustainable development by optimizing energy consumption (such as servo motor energy-saving technology) and reducing material waste (AI intelligent nesting system).

Masda equipment adopts efficient hydraulic system and low noise design, and its energy consumption is 18% lower than that of traditional models, which meets the strict requirements of the European and American markets for environmental certification.

4. Domestic substitution is accelerating, and technological autonomy has broken through

Chinese automation equipment companies are turning from “following” to “leading”.

With high cost-effectiveness and fast-response localized services, domestic equipment continues to rise in the global market share (the market share of domestic industrial robots will exceed 52% in 2023).

Relying on its independently developed CNC system and core components, Masda has broken the monopoly of foreign brands. Its products have been exported to more than 50 countries and have become the preferred brand in emerging markets such as Southeast Asia and the Middle East.

5. Downstream industry expansion drives demand growth

The demand for high-precision sheet metal parts in emerging fields such as new energy and semiconductors has surged.

For example, the processing of lithium battery shells needs to take into account both strength and lightness.

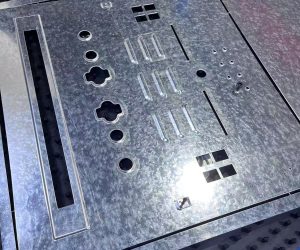

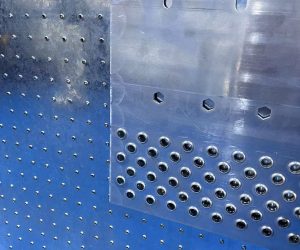

Masda CNC punching machines can achieve one-time forming of complex holes through multi-axis linkage technology, which increases efficiency by 40%.

In addition, the popularity of smart homes has promoted the increase in investment in automated production lines in the kitchenware and cabinet industry, further expanding the market space.

Masda's Commitment and Outlook

In the face of industry changes, Masda continues to optimize its product matrix with “precision, efficiency, and ease of use” as the core.

In the future, we will integrate system and automation technology, launch smart factory solutions adapted to the industrial Internet, and help global customers seize the opportunity of smart manufacturing.

To explore more innovative technologies, please visit Masda’s official website, or contact our professional team to start your sheet metal processing upgrade journey!

RELATED NEWS