-

Masda CNC Punching Machine-Typing Technology

Masda CNC Punching Machine-Typing TechnologyI. Origin and Technological Development of Typing Technology Typing technology originated from traditional stamping technology.With the development of CNC punching machines, its accuracy and efficiency have been significantly improved. Modern CNC punching machines can accurately stamp letters, numbers or symbols on sheet metal materials through pr……

Jun,06 2025

Jun,06 2025

-

Masda CNC Punching Machine - Flanging Process

Masda CNC Punching Machine - Flanging ProcessI. Origin and Technological Development of Flanging Process The flanging process originated from the field of traditional metal stamping. In the early days, the edges of sheet metal materials were bent by dies to form vertical straight edges or flanges to meet the needs of connection, strengthening or aesthetics. In the mid-20th century, with the ……

Jun,03 2025

Jun,03 2025

-

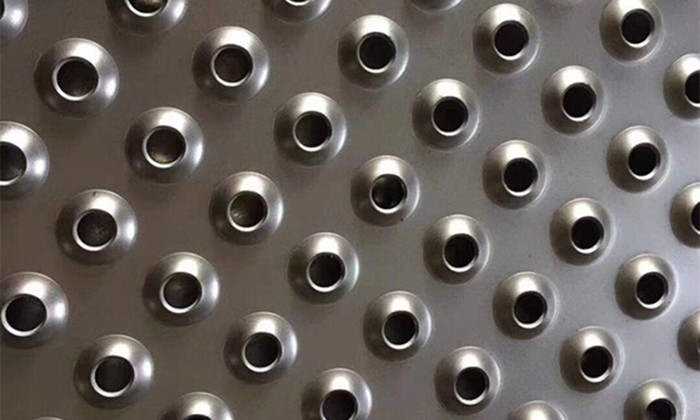

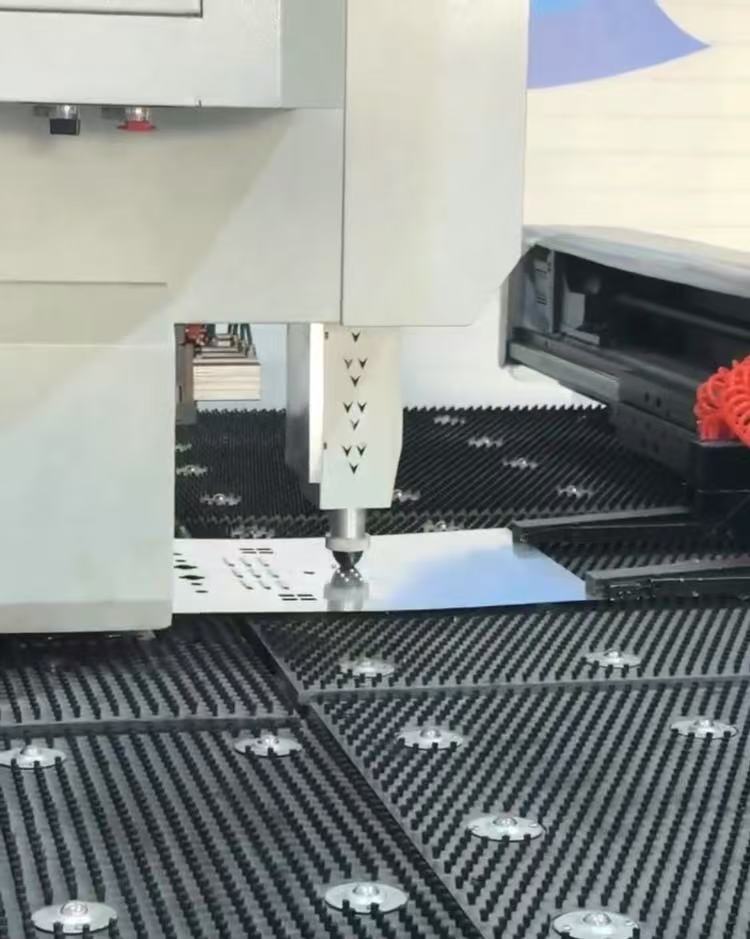

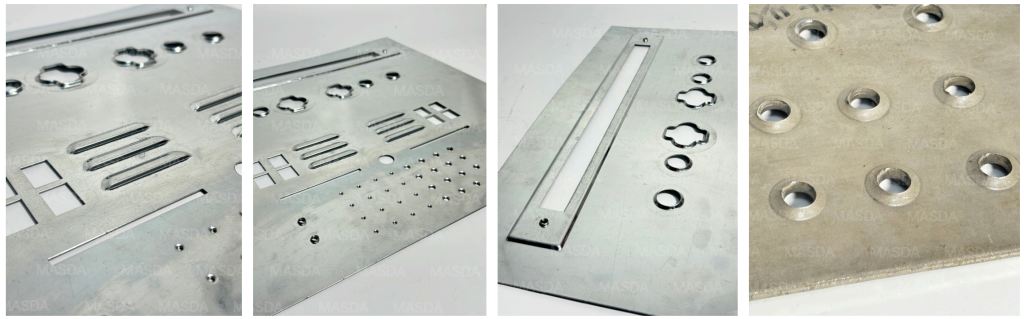

Masda CNC Punching Machine - Fisheye Hole Process

Masda CNC Punching Machine - Fisheye Hole ProcessAs a special punching hole type, fisheye hole process is named for its unique "fisheye" structure. In recent years, it has attracted much attention in the field of precision sheet metal processing. Its process originates from the demand for electronic connector manufacturing, especially the processing requirements of high-density and small-pitch t……

May,30 2025

May,30 2025

-

Masda CNC Punching Machine - Tapping and Threading Process

Masda CNC Punching Machine - Tapping and Threading ProcessI. The Origin and Technological Evolution of Tapping and Threading The tapping and threading process originated from the thread forming needs in traditional metal processing. In the early days, the internal threads were cut in pre-drilled holes by hand taps (thread taps). With the development of industry, the introduction of CNC technology in ……

May,27 2025

May,27 2025

-

Masda CNC Punch Machine - Door Lock Pressing Process

Masda CNC Punch Machine - Door Lock Pressing ProcessI. The Origin and Technological Evolution of Door Lock Pressing The door lock pressing process originated from the stamping forming needs in traditional lock manufacturing. In the early days, it relied on manual punches and simple molds to complete the rough processing of the lock body structure. With the popularization of smart door locks, th……

May,26 2025

May,26 2025

-

Masda CNC Punching Machine-Bridge Pulling Process

Masda CNC Punching Machine-Bridge Pulling ProcessI. Origin and Definition of Bridge Pulling Process Bridge pulling process is a key forming technology in sheet metal processing, which originated from the upgrading demand of traditional stamping process. With the popularization of CNC punching machines (NC), the bridge pulling process has gradually developed from simple punching to a complex form……

May,23 2025

May,23 2025

-

Masda CNC Punching Machine - Venetian Blinds Process

Masda CNC Punching Machine - Venetian Blinds Process一.、The Origin and Function of Venetian Blinds Venetian blinds can be traced back to the wooden window lattice structure in ancient China, and later improved in Europe to become a practical design that combines sunshade and ventilation. In the field of sheet metal processing, the venetian blinds process is formed by stamping metal sheets, which i……

May,16 2025

May,16 2025

-

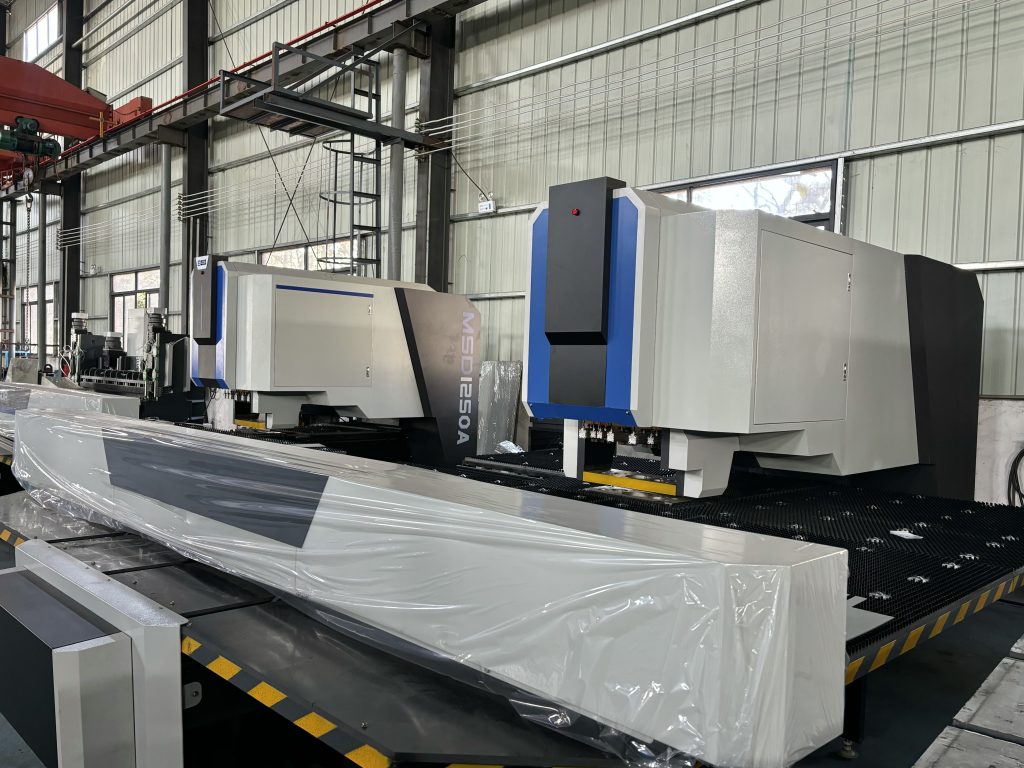

Masda helps Indonesia's leading door industry achieve capacity upgrade and open a new chapter in sheet metal automation

Masda helps Indonesia's leading door industry achieve capacity upgrade and open a new chapter in sheet metal automationIn the Indonesian door industry market, a leading company embarked on a cross-border search journey due to capacity bottlenecks. Faced with challenges such as low labor efficiency, unstable process quality, and urgent need for factory expansion, the company spent two years investigating six Chinese equipment suppliers and finally chose to reach ……

May,13 2025

May,13 2025

-

Trends and developments in automation equipment: leading the future innovation of the sheet metal processing industry

Trends and developments in automation equipment: leading the future innovation of the sheet metal processing industryUnder the wave of intelligent transformation of the global manufacturing industry, automation equipment is becoming the core engine to promote the high-quality development of the sheet metal processing industry. As a manufacturer focusing on the research and development of bending machines, CNC punching machines and sheet metal composite machine……

May,07 2025

May,07 2025

-

Masda sheet metal intelligent manufacturing unmanned production line: an automation revolution of efficiency and precision

Masda sheet metal intelligent manufacturing unmanned production line: an automation revolution of efficiency and precisionFull-process intelligent collaboration redefines sheet metal manufacturing In the wave of industrial intelligence, Masda launched a sheet metal intelligent manufacturing unmanned production line, with a robotic arm as the core drive, to create an efficient production closed loop of "unmanned + digitalization". From sheet loading to finished prod……

Apr,15 2025

Apr,15 2025

-

Masda's intelligent sheet metal equipment empowers four core areas and unlocks new possibilities for efficient production

Masda's intelligent sheet metal equipment empowers four core areas and unlocks new possibilities for efficient productionToday, as the wave of intelligent manufacturing sweeps the world, the sheet metal processing industry is undergoing a transformation from traditional crafts to intelligent manufacturing. As an innovator in the field of sheet metal equipment, we use flexible bending centers, intelligent CNC punching machines and sheet metal composite machines as ……

Apr,08 2025

Apr,08 2025

-

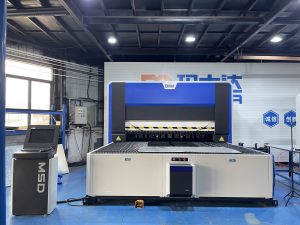

Masda: 18 years of deep cultivation in intelligent manufacturing and sheet metal automation

Masda: 18 years of deep cultivation in intelligent manufacturing and sheet metal automationToday, as the wave of intelligent manufacturing sweeps the world, Masda, founded in 2007, has built a full industrial chain layout covering R&D, production, and services with 18 years of deep cultivation in the industry. Its independently developed flexible bending center, CNC punch press and other intelligent equipment have not only set off……

Mar,24 2025

Mar,24 2025