-

How Does Masda Bending Center Solve the Pain Points in Fire Cabinet Manufacturing?

How Does Masda Bending Center Solve the Pain Points in Fire Cabinet Manufacturing?In the fire cabinet production workshop, the bending process directly determines the structural stability, sealing performance, and assembly accuracy of the product. As the core carrier for storing emergency fire-fighting equipment, fire cabinets must not only withstand long-term use but also meet strict dimensional tolerance standards.Core Bendin……

Jan,31 2026

Jan,31 2026

-

Masda Small Bending Center: The Smart Choice for Cost-Effective Sheet Metal Processing

Masda Small Bending Center: The Smart Choice for Cost-Effective Sheet Metal ProcessingMasda, a powerful brand specializing in sheet metal processing equipment manufacturing, has launched a small bending center that precisely addresses industry needs. With its ultra-high cost-effectiveness, professional-grade configuration, and stable performance, it has become the preferred equipment for small and medium-sized sheet metal enterprises u……

Jan,28 2026

Jan,28 2026

-

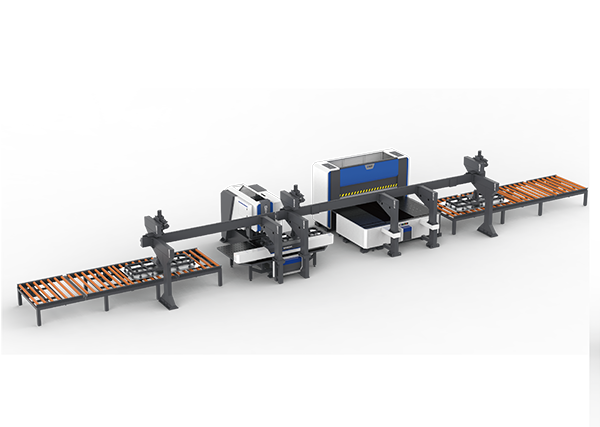

Masda Builds an Intelligent Sheet Metal Production Line for a Leading Electrolyzer Company

Masda Builds an Intelligent Sheet Metal Production Line for a Leading Electrolyzer CompanyAchieving Unmanned Automated Processing Workshops With 20 years of experience in the sheet metal equipment field, Masda has consistently empowered the sheet metal industry with customized solutions. Recently, its expertise earned the trust of a leading Chinese electrolyzer company, enabling them to build a dedicated sheet metal forming production line……

Sep,11 2025

Sep,11 2025

-

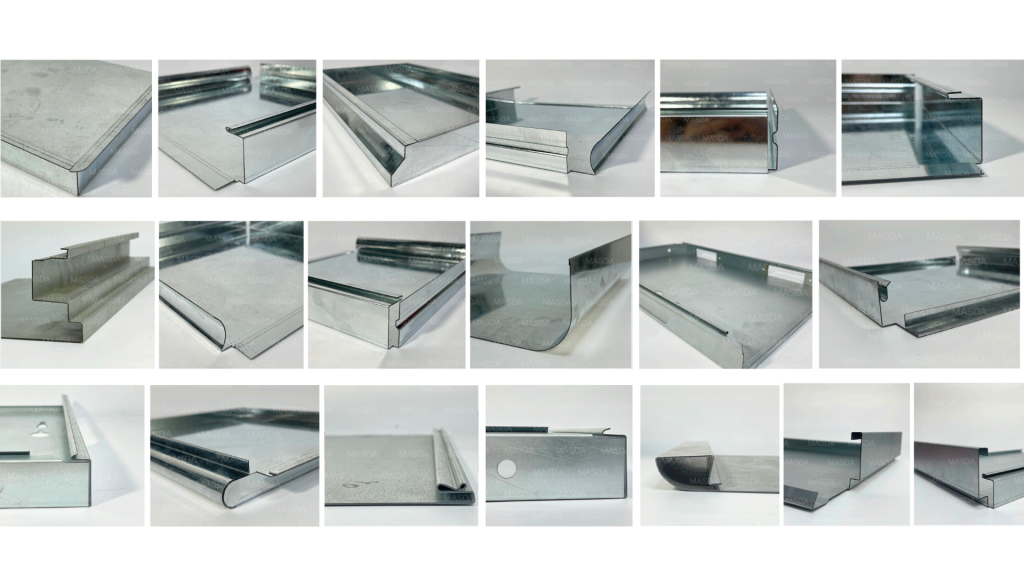

Masda Bending Machine - Rebending Process

Masda Bending Machine - Rebending ProcessIn the sheet metal processing industry, the rebending process (also known as "rebending frame bending" or "box hemming") is a highly efficient and high-strength joining and forming technology. Originating from the high demands for structural strength and aesthetic integrity in sheet metal parts, rebending process it has become increasingly popular……

Aug,23 2025

Aug,23 2025

-

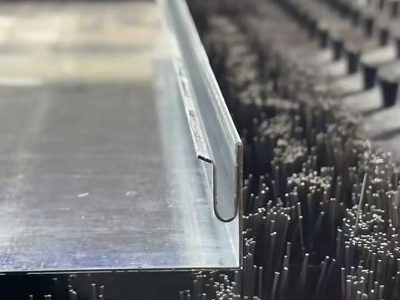

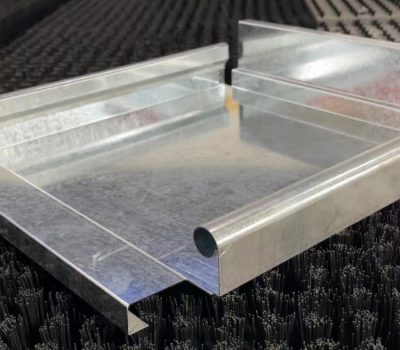

Masda Bending Machine - Roller Lashing Process

Masda Bending Machine - Roller Lashing ProcessIn the pursuit of efficient, aesthetically pleasing, and reliable sheet metal joining, the roller lashing process (also known as roll lapping) stands out with its unique advantages. Originating in the mid-to-late 20th century, this technology has gradually matured with the surge in demand for precision sheet metal processing and the increasing dem……

Jul,29 2025

Jul,29 2025

-

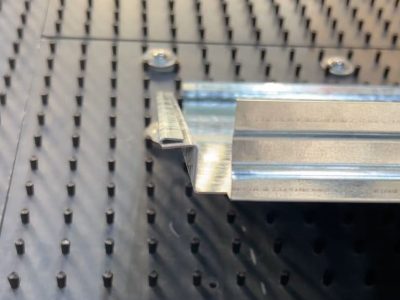

Masda Bending Machine - Back-Bending Process

Masda Bending Machine - Back-Bending ProcessIn sheet metal processing, back-bending is the key process for the bending machine to achieve a closed box structure. Masda CNC bending machine can efficiently complete such complex forming with high-precision multi-axis positioning and intelligent program control.The origin of the back-bending process • Functional demand drive: In order to me……

Jul,23 2025

Jul,23 2025

-

Masda Bending Machine - Edge Beating Process (upper beating, lower beating and reverse beating)

Masda Bending Machine - Edge Beating Process (upper beating, lower beating and reverse beating)In sheet metal , edge beating process is a finishing process in which the bending machine flattens the edge of the plate, which is mainly used to strengthen the edge, eliminate burrs or build a closed structure. Masda CNC bending machine meets diverse needs edge beating process through three processes: upper beating, lower beating and reverse beat……

Jul,12 2025

Jul,12 2025

-

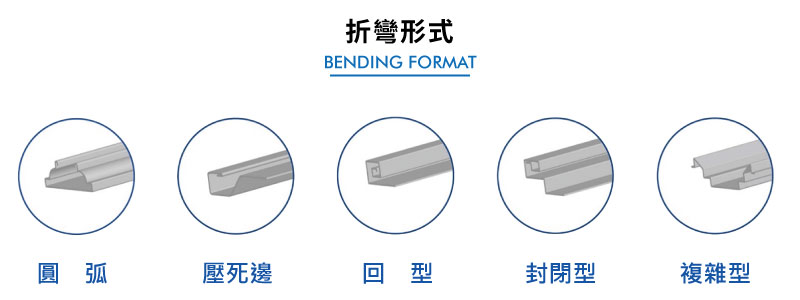

Masda Bending Machine - Arc Bending Process

Masda Bending Machine - Arc Bending ProcessIn sheet metal processing, arc bending process beyond right angles gives the product an elegant streamline and unique functionality. Masda CNC bending machine, with its high-precision control capability, makes complex large-radius arc forming efficient and accurate.Origin of arc bending: It stems from the improvement of sheet metal aesthetic ……

Jun,28 2025

Jun,28 2025

-

Masda Automatic Bending Machine - Upper Bending and Lower Bending Process

Masda Automatic Bending Machine - Upper Bending and Lower Bending ProcessIn the field of sheet metal processing, bending is the key process to shape flat metal into the required angle.Masda autoamtic bending machine uses two core processes, upper bending (Air Bending) and lower bending (Bottoming/Coining), to give various sheet metal parts precise shapes. It is crucial to understand their differences.The origin of upper be……

Jun,21 2025

Jun,21 2025

-

Masda CNC Punching Machine - Corner Cutting Process

Masda CNC Punching Machine - Corner Cutting ProcessIn the field of sheet metal processing, corner cutting process is one of the indispensable core processes on CNC punching machines. It is specifically used to accurately cut a notch of a specific shape (most commonly a rectangle or square) on the edge or corner of a metal sheet. Why is corner cutting needed? Assembly avoidance: This is the……

Jun,15 2025

Jun,15 2025

-

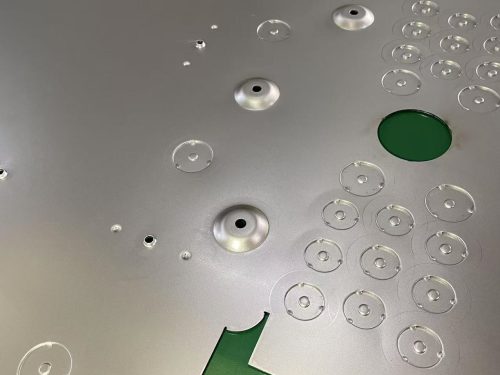

Masda CNC Punch Machine- Countersunk Hole Process

Masda CNC Punch Machine- Countersunk Hole Process1. The Origin and Technological Development of Countersunk Hole Process The countersunk hole process develops with the demand for precision assembly. CNC punch presses use multi-stage stamping or rotation processing technology to make the screw head flush with the sheet metal surface, improving the aesthetics and stability of the assembly.2. Applicati……

Jun,10 2025

Jun,10 2025

-

Masda CNC Punching Machine - Knock-out Hole Process

Masda CNC Punching Machine - Knock-out Hole ProcessThe knock-out hole process originated from the assembly requirements of electrical boxes and chassis. Traditional manual hole opening is inefficient and has poor precision. Masda CNC Punching Machine realizes standardized and modular installation by prefabricating holes with connecting plates.I.Application scenarios: It is mainly used in dist……

Jun,09 2025

Jun,09 2025