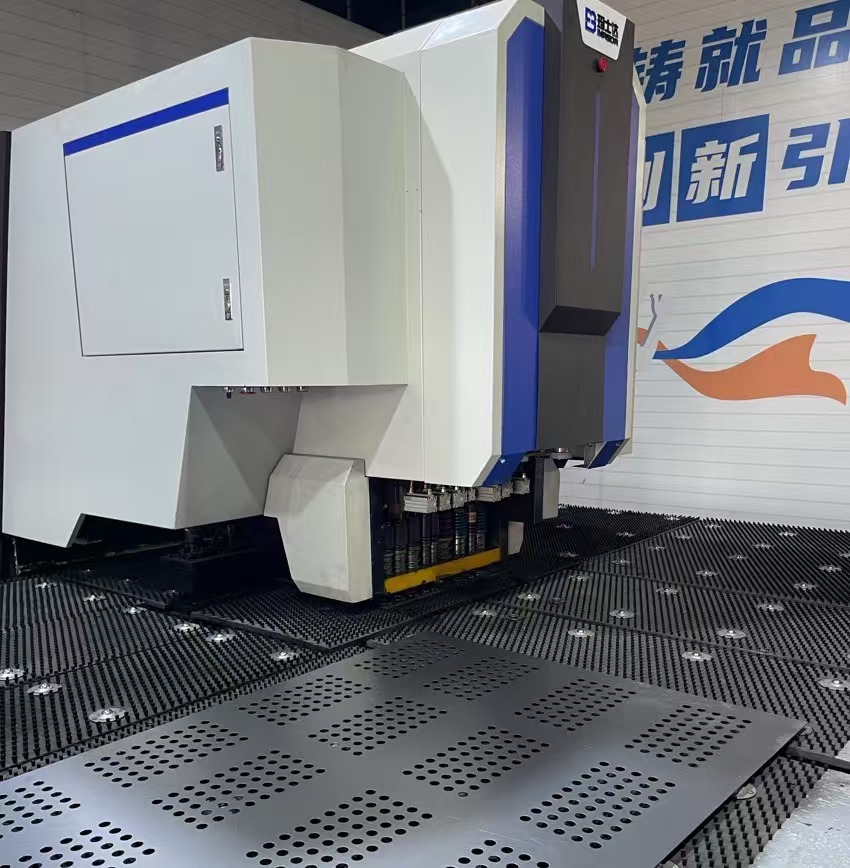

Masda Small Bending Center: The Smart Choice for Cost-Effective Sheet Metal Processing

Masda, a powerful brand specializing in sheet metal processing equipment manufacturing, has launched a small bending center that precisely addresses industry needs. With its ultra-high cost-effectiveness, professional-grade configuration, and stable performance, it has become the preferred equipment for small and medium-sized sheet metal enterprises undergoing upgrades and transformations.

It not only eliminates the redundant design of traditional equipment but also maintains high-quality core configurations while offering a competitive price, providing efficient solutions for processing various sheet metal materials such as stainless steel, carbon steel, aluminum, and copper.

Wide Range of Applications: Adaptable to Diverse Sheet Metal Processing

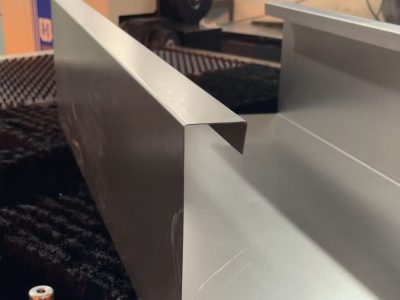

1. Core Applicable Materials: It can stably process mainstream sheet metal materials with a thickness of 1.2mm or less, including stainless steel, carbon steel, aluminum plates, and copper plates. Whether it’s high-hardness thin stainless steel sheets or easily deformable aluminum alloy plates, it can achieve precise forming, meeting the material performance requirements of different industries.

2. Typical Application Fields: Small cabinet doors and drawer frames in the commercial kitchen equipment industry; server accessories and instrument casings in the electronics industry; small ceiling keels and decorative lines in the architectural decoration field; small interior brackets and connectors in the automotive parts industry; and distribution box accessories and furniture hardware in the hardware products industry.

Core Function Analysis: Professional Configuration, Efficient and Precise

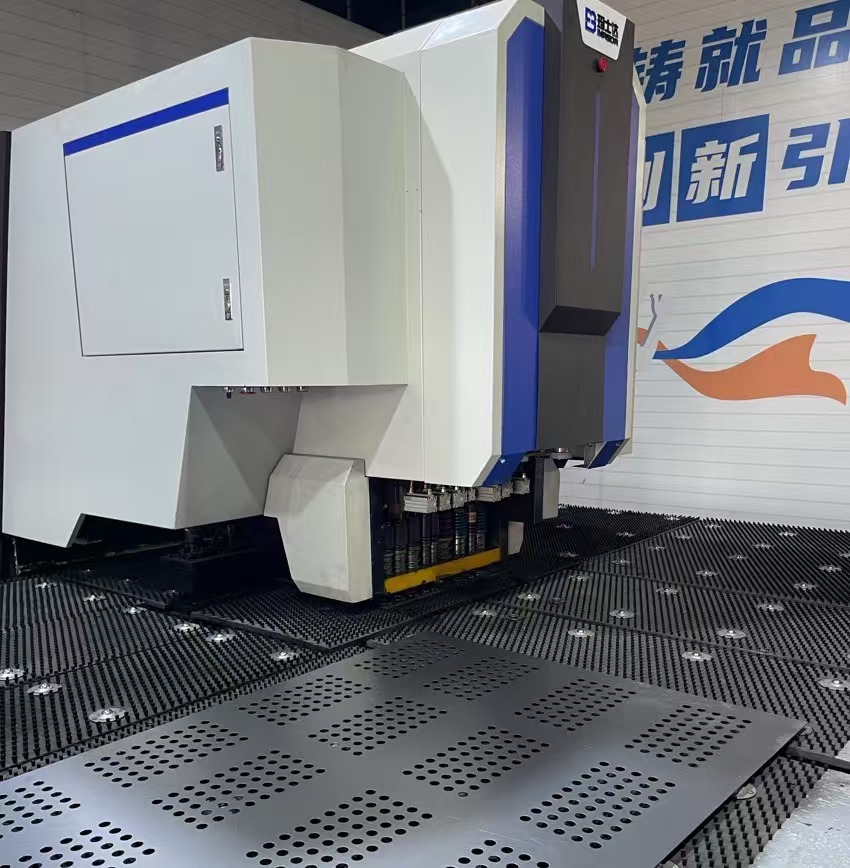

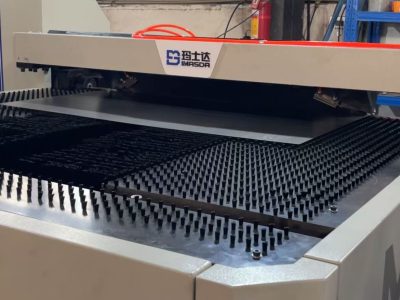

The Masda small bending center eliminates redundant functions and focuses on core processing needs, creating a stable and reliable processing experience with its professional-grade configuration. Key features include:

1. Professional computer control system, convenient and efficient operation: The system supports simple graphical programming, allowing even beginners to quickly get started, reducing personnel training costs.

2. Full servo bus control, improving both precision and efficiency: Adopting a full servo bus drive design, it offers faster response speed and more precise motion control.

3. Stable and reliable basic configuration, adaptable to diverse processing needs: Supports quick switching between different product sizes, adapting to the bending needs of various small sheet metal parts without complex debugging.

Summary of Core Advantages: High-Performance Equipment at a Competitive Price

Masda’s small bending centers consistently adhere to the philosophy of “practical configuration and reasonable pricing.” Their core advantages directly address the pain points of small and medium-sized sheet metal enterprises:

firstly, exceptional cost-effectiveness, providing professional-grade processing performance at an affordable price;

secondly, reliable after-sales service, including tax-inclusive pricing and a one-year warranty in China, ensuring peace of mind for businesses;

thirdly, convenient operation and simple maintenance, reducing personnel and operating costs for enterprises.

For small and medium-sized sheet metal processing enterprises seeking efficiency, precision, and cost-effectiveness, Masterbend’s small bending centers are both a powerful tool for improving production efficiency and an excellent choice for controlling costs and enhancing market competitiveness.

RELATED NEWS