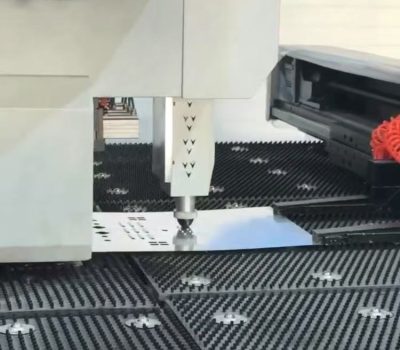

Masda CNC Punching Machine – Tapping and Threading Process

I. The Origin and Technological Evolution of Tapping and Threading

The tapping and threading process originated from the thread forming needs in traditional metal processing.

In the early days, the internal threads were cut in pre-drilled holes by hand taps (thread taps).

With the development of industry, the introduction of CNC technology in the 20th century promoted the innovation of tapping technology, especially the application of CNC punching machines (NC), which realized high-precision and high-efficiency automated thread processing.

II. Application scenarios and sheet metal material adaptation

Tapping and threading are widely used in sheet metal parts that require high-precision threaded connections. The main scenarios include:

1. Electronic equipment: such as server chassis, communication cabinets, etc., need to process high-density threaded holes on cold-rolled steel plates to adapt to screw fastening needs.

2. Automobile manufacturing: Door hinges, chassis brackets, etc. are made of stainless steel or aluminum alloy, and the tapping process is used to enhance the connection strength and vibration resistance.

3. Building hardware: In metal curtain walls and ventilation components, the tapping process can achieve weather-resistant thread structures on galvanized sheets.

III. Core functions and technical advantages

The tapping process achieves three core functions through CNC punching machines:

1. High-precision forming: The thread size error can be controlled within ±0.1mm, meeting the high-requirement fields such as aerospace.

2. Efficient production: Support batch processing and rapid mold change, such as in-mold tapping machines can simultaneously complete punching and thread forming, and the efficiency is increased by more than 50%.

3. Material adaptability: It can process stainless steel, aluminum alloy and high carbon steel, and adapt to materials of different hardness by adjusting the tap type (such as cutting taps, extrusion taps).

Iv. Forming process and key technologies

The forming process of CNC punching machine tapping includes the following key steps:

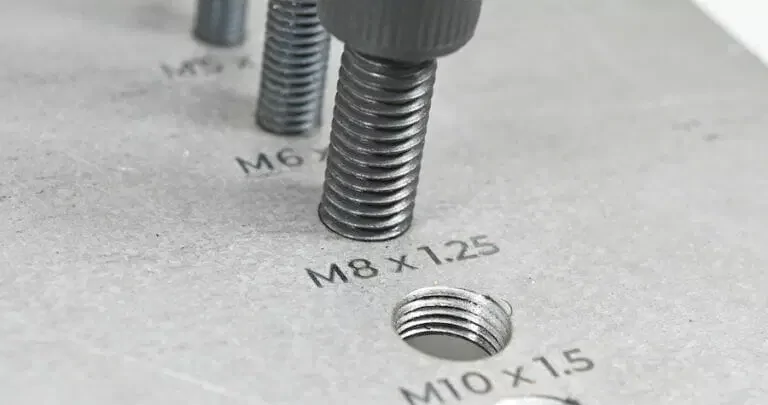

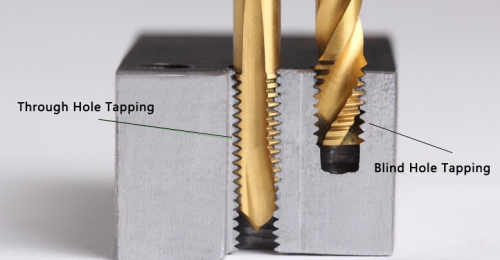

1. Mold selection: Select straight groove taps (through holes) or spiral groove taps (blind holes) according to the material thickness and thread specifications. Extrusion taps are suitable for chipless processing of ductile materials (such as aluminum).

2. Budding process

Principle: Use the die of the CNC punch press to locally extrude and stretch the sheet to form a boss or protrusion on the surface of the sheet, which is usually used to increase the connection strength or facilitate subsequent assembly.

3. Tapping process

Principle: The power head of the CNC punch press drives the tap to rotate and process the internal thread on the sheet to connect with the bolt or screw.

Advantages: It can directly process standard internal threads on the workpiece with high precision to meet different connection requirements; compared with other connection methods, it has better tightness and sealing; threads of different specifications and precisions can be processed as needed.

Application: It is widely used in machinery manufacturing, construction, furniture and other industries, such as installation holes of mechanical equipment, connection parts of building hardware, and assembly parts of furniture.

Process advantages of Masda CNC punch press

Masda CNC punch press can stably process a variety of sheet metal materials, support rapid switching of modular molds, and adapt to the multi-specification requirements of door lock pressing.

The equipment is equipped with a CNC system, which can automatically typeset and identify CAD drawings after importing them, and uses rigid tapping synchronous control technology to reduce tool wear and improve tapping efficiency by 30%.

RELATED NEWS