Masda CNC Punching Machine – Knock-out Hole Process

The knock-out hole process originated from the assembly requirements of electrical boxes and chassis.

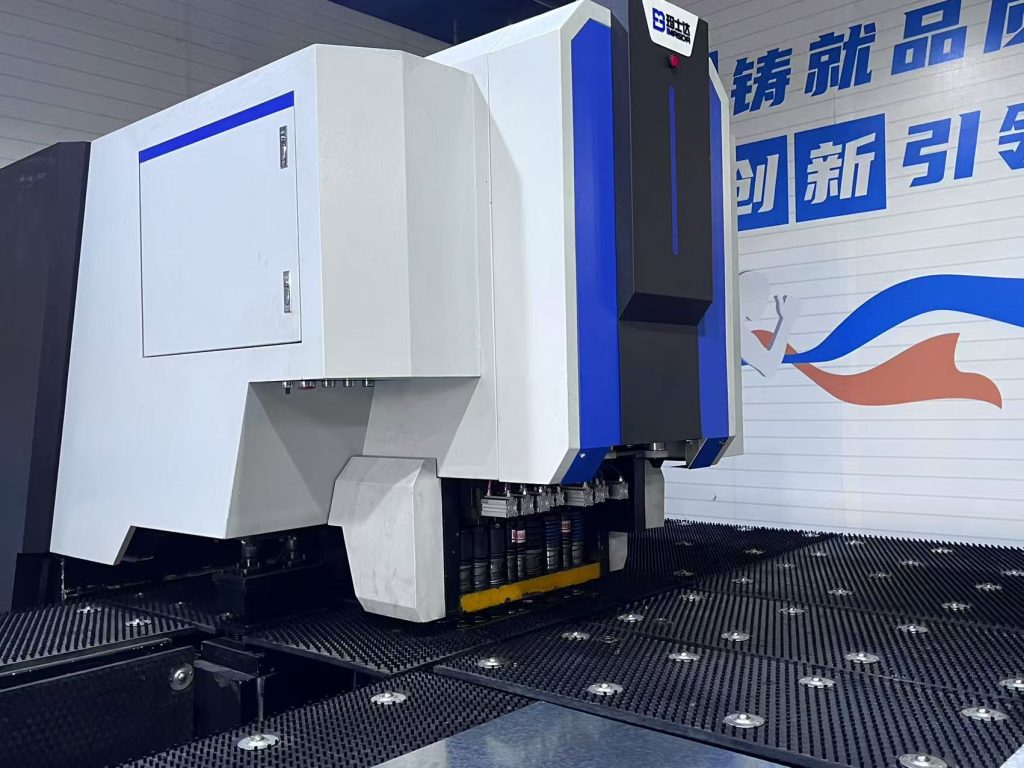

Traditional manual hole opening is inefficient and has poor precision. Masda CNC Punching Machine realizes standardized and modular installation by prefabricating holes with connecting plates.

I.Application scenarios:

It is mainly used in distribution boxes, control cabinets, communication equipment chassis and other components that require reserved installation holes.

Applicable materials are mainly cold-rolled plates and galvanized plates with a thickness of ≥1.2mm to ensure that the connecting plates have sufficient strength.

II.Function:

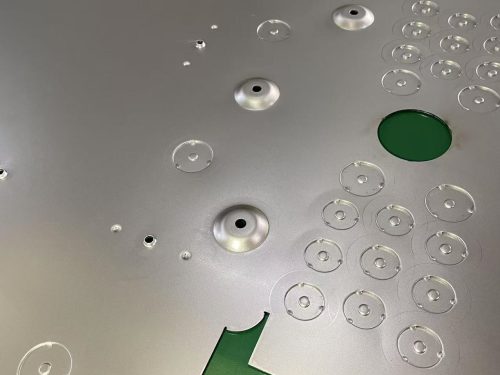

Reserved installation position: knock-out holes process with thin sheet connections is convenient for subsequent installation of cable connectors, bolts, etc.

Modular design: Standardized hole positions improve assembly compatibility and reduce secondary processing costs.

Protection function: Before installation, the connecting plate closes the hole position to prevent foreign matter from entering the interior.

III.Forming process:

Mold design: A “punch + die” combination is adopted, and the bottom of the punch has a ring cutter to cut the material during punching but not completely separate it.

Stamping: After the CNC punch press is positioned, the punch presses down to cut out the hole outline, and the connecting piece is connected to the plate through the weak point.

Knock out the thin sheet: During installation, the connecting piece is knocked by external force to break it off, forming a complete hole position.

Edge treatment: Remove burrs on the edge of the hole to ensure smooth passage of the installation parts.

Technical advantages: Reduce assembly time, no additional drilling process required; avoid hole position deviation and improve installation success rate; adapt to different hole diameter requirements, and the mold can be quickly replaced

RELATED NEWS