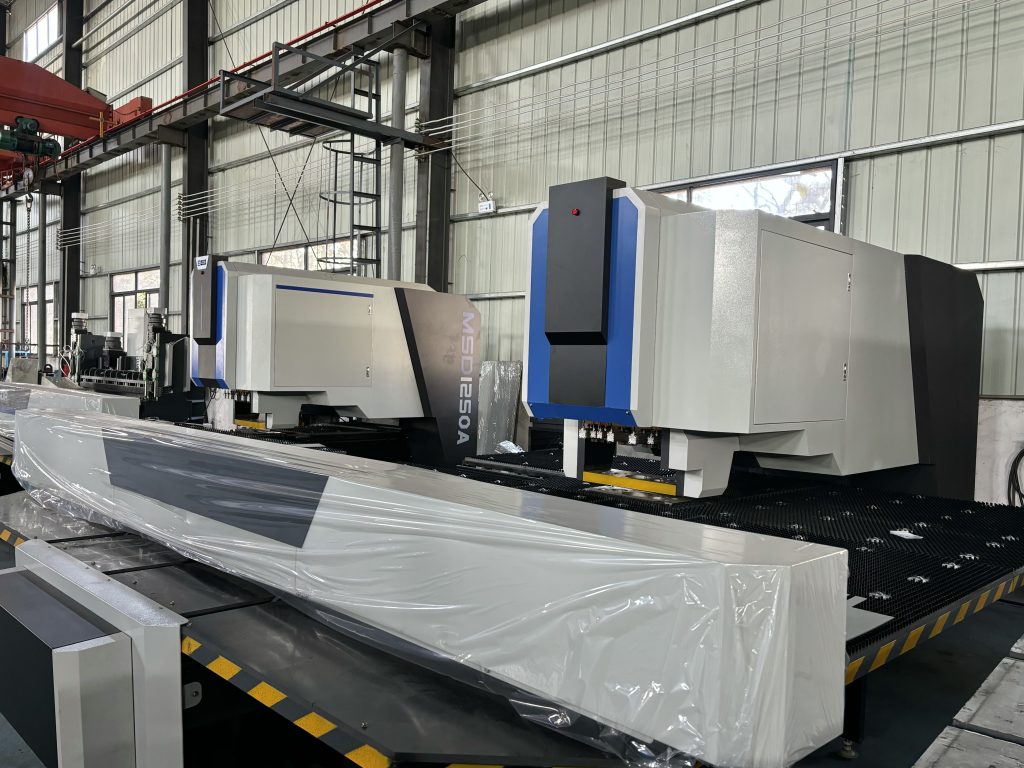

Masda CNC Punching Machine – Corner Cutting Process

In the field of sheet metal processing, corner cutting process is one of the indispensable core processes on CNC punching machines.

It is specifically used to accurately cut a notch of a specific shape (most commonly a rectangle or square) on the edge or corner of a metal sheet.

Why is corner cutting needed?

Assembly avoidance: This is the main purpose. When two sheet metal parts need to be assembled at right angles or a specific angle, corner cutting can effectively avoid interference and collision between adjacent edges, ensuring a tight and smooth assembly effect.

It is widely used in products such as chassis, cabinets, and brackets.

Functional expansion: Reserve space for installing screws, cables or other components.

Weight reduction/optimized design: Cut off excess material in non-critical areas.

Application scenarios:

The corner cutting process is widely used in the processing of various types of metal plates, including:

Carbon steel plate: (SPCC, SECC, etc.)

Stainless steel plate: (SUS304, SUS430, etc.)

Aluminum plate: (such as 5052, 6061, etc.)

Galvanized plate, copper plate, etc.

Functional advantages:

Improve assembly accuracy and efficiency: Eliminate assembly interference, ensure that components fit tightly, reduce on-site grinding, and significantly improve production efficiency and product quality.

Simplify subsequent processes: Accurately reserve positions before bending to avoid conflicts that are difficult to handle after bending.

Design flexibility: Support more complex sheet metal structure design.

Forming principle:

The corner cutting forming process is efficient and precise:

Programming and positioning: Engineers accurately set the position, size (length, width, depth) and angle of the corner cutting in the programming software according to the design drawings. The program is imported into the Masda CNC punch press.

Mold selection: Select a special rectangular knife (square knife) or special shape tool according to the notch size.

Precision punching: Masda CNC punching machine drives the mold to move at high speed. Under program control, through single or multi-step punching action, the material is accurately cut at the specified edge of the plate to form the required notch.

Its high-rigidity body and precise positioning system ensure that the cut edge is flat and the size is consistent (accuracy can reach ±0.1mm).

Efficient completion: The entire process is completed automatically, with fast speed and good consistency, suitable for mass production.

Summary:

Corner cutting is a key pre-processing step to ensure the smooth assembly and overall quality of sheet metal components.

With its excellent rigidity, precision and flexible programming capabilities, Masda CNC punching machine provides efficient and accurate corner cutting processing solutions for various metal sheets, and is a reliable partner to improve your sheet metal production efficiency and product quality.