Masda CNC Punching Machine-Bridge Pulling Process

I. Origin and Definition of Bridge Pulling Process

Bridge pulling process is a key forming technology in sheet metal processing, which originated from the upgrading demand of traditional stamping process.

With the popularization of CNC punching machines (NC), the bridge pulling process has gradually developed from simple punching to a complex forming method that accurately controls the deformation of materials through molds.

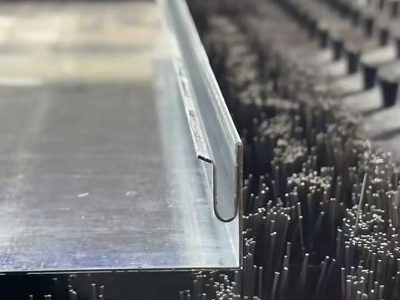

Its core is to form a “bridge-shaped” structure by locally stretching the sheet metal material through stamping, which is both functional and decorative.

II. Application scenarios and material adaptation

The bridge pulling process is widely used in sheet metal parts that require high strength and lightweight design. Typical scenarios include:

1. Electronic equipment: such as server chassis, communication cabinets, etc., through the bridge pulling structure to enhance heat dissipation efficiency and improve overall rigidity.

2. Automobile manufacturing: used for door reinforcement ribs, chassis brackets, etc., through the bridge design to disperse the load and improve impact resistance.

3. Architectural decoration: metal curtain walls, ventilation partitions and other scenes, the bridge pulling process can not only reduce weight, but also form a modern industrial aesthetic texture.

Applicable materials: cold-rolled steel plates, stainless steel, aluminum alloys, etc., and mold parameters need to be adjusted according to the ductility of the material.

III. Core functions and advantages

1. Structural reinforcement: The bridge-shaped protrusion can improve the bending resistance of sheet metal parts and reduce the risk of deformation, especially suitable for thin plate processing.

2. Heat dissipation optimization: The bridge-shaped gap promotes air circulation and is widely used in the shell design of heating equipment.

3. Lightweight design: Compared with traditional welding reinforcement ribs, the bridge-drawing process reduces material redundancy and component weight through one-piece molding.

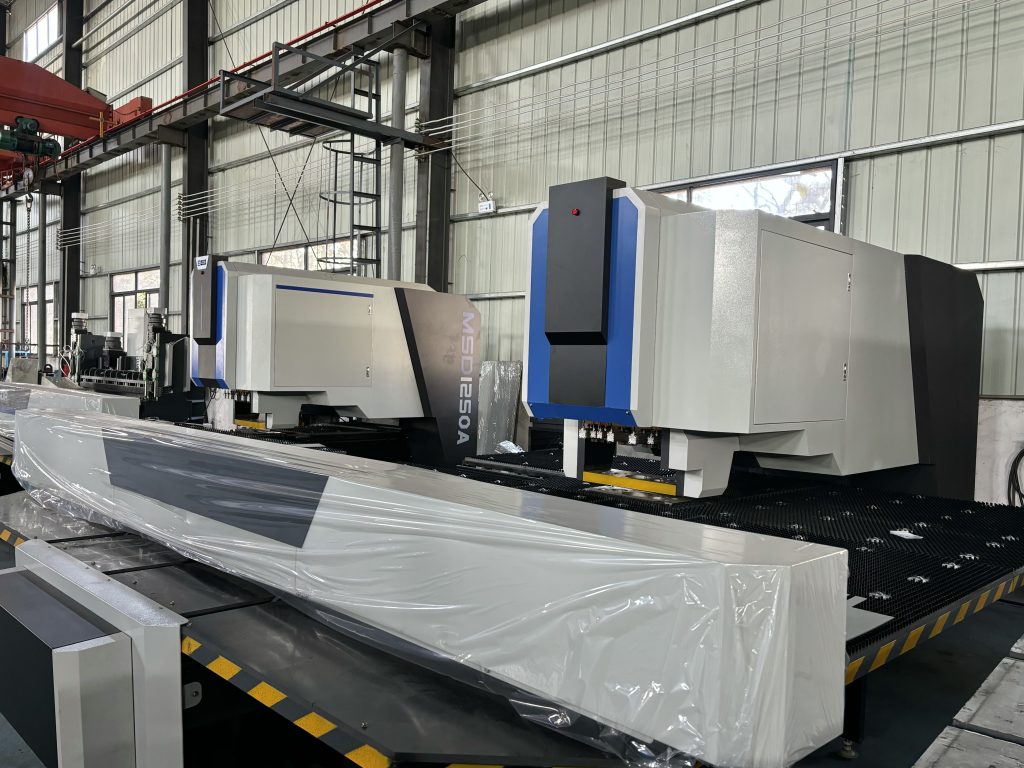

4. Cost efficiency: Masda CNC punching machine supports fast switching of multiple molds to achieve batch production, and the single molding accuracy can reach ±0.1mm.

IV. Molding process and technical points

The molding of the bridge-drawing process depends on the precise control of the CNC punching machine. The key steps are as follows:

1. Mold design: Use U-shaped or stepped molds to control the height and angle of the bridge to avoid material cracking.

2. Material pretreatment: Annealing treatment is performed on high-hardness materials to improve ductility; aluminum alloys need to control stamping lubrication to reduce surface scratches.

3. Quality control: Optical inspection equipment is used to monitor the bridge size in real time, and the springback compensation algorithm after stamping is combined to ensure the forming accuracy.

As a key technology in sheet metal processing, the bridge drawing process achieves a deep integration of function and structure through the precise control of the CNC punch press.

With its high precision and intelligent characteristics, Masda CNC punch press provides the industry with efficient and reliable bridge drawing solutions, helping customers achieve product innovation and cost optimization in the fields of electronics, automobiles, and home appliances.

RELATED NEWS