Masda Bending Machine – Rebending Process

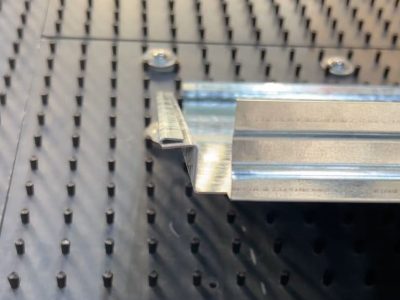

In the sheet metal processing industry, the rebending process (also known as “rebending frame bending” or “box hemming”) is a highly efficient and high-strength joining and forming technology.

Originating from the high demands for structural strength and aesthetic integrity in sheet metal parts, rebending process it has become increasingly popular with advancements in CNC bending technology, making it an ideal choice for manufacturing enclosed or semi-enclosed box structures.

Wide Applications:

The rebending process is applicable to a variety of sheet metal materials, particularly the following:

• Galvanized steel: Widely used in equipment enclosures such as control cabinets, distribution boxes, and network cabinets.

• Aluminum/aluminum alloy: Used in various instrument enclosures, protective covers, and lightweight equipment components.

• Stainless steel: Commonly used in enclosures for equipment in industries such as food, medical, and chemical industries that require hygiene and corrosion resistance.

Core Features and Advantages:

• High-Strength Structure: The four interlocking bends create a rigid frame structure with exceptional torsional and compressive resistance.

• Weld-free, seamless connection: Avoids deformation and smoke pollution caused by welding, achieving a clean, aesthetically pleasing, integrated appearance.

• Material and cost savings: Typically, no additional connectors or welding steps are required, simplifying the production process and reducing overall costs.

• Excellent sealing: When used with sealing strips, it easily meets the required IP65 protection level, providing dust and water resistance.

Empowering high-end sheet metal manufacturing

The re-forming process is a key indicator of the technical level and equipment capabilities of sheet metal processing companies. It perfectly embodies the leap from “bending” to “constructing” in bending technology.

Masda’s intelligent CNC press brake, with its stable performance, superb positioning accuracy, and powerful programming capabilities, is a reliable guarantee for implementing complex re-forming processes, helping you efficiently produce a variety of sheet metal boxes and cabinets with strong structures and exquisite appearance.

RELATED NEWS