How Does Masda Bending Center Solve the Pain Points in Fire Cabinet Manufacturing?

In the fire cabinet production workshop, the bending process directly determines the structural stability, sealing performance, and assembly accuracy of the product.

As the core carrier for storing emergency fire-fighting equipment, fire cabinets must not only withstand long-term use but also meet strict dimensional tolerance standards.

Core Bending Process for Fire Cabinets: Precision and Stability are the Bottom Line

The bending process of fire cabinets seems simple, but it actually hides many critical requirements that directly affect whether the product is qualified:

1. Core bending requirements: Primarily four-sided closed bending, hemming, and corner avoidance to ensure that the cabinet body is securely joined and meets sealing requirements.

2. Surface and structural requirements: Bending edges must be free of burrs and scratches to avoid affecting subsequent painting; process gaps need to be created at corners to prevent tool collision and stress concentration cracking.

Traditional Fire Cabinet Bending Processing: Bottlenecks in Efficiency and Quality

Currently, many manufacturers still use manual bending or ordinary mechanical bending to process fire cabinets, and the problems exposed during this process are difficult to avoid:

1. Reliance on skilled workers, high labor costs, and poor stability

Manual bending completely relies on the worker’s experience to control the angle and positioning. Although ordinary mechanical bending has basic automation, each bend requires manual recalibration. Workers repeatedly adjust the workpiece position, which not only increases labor intensity but also results in poor consistency between different workers and different time periods. Angle deviations and dimensional errors are frequent, and the scrap rate is generally above 5%.

2. Low efficiency, limited by changeover and mass production

Traditional mechanical bending requires manual mold adjustment and parameter setting. Mold changeover alone takes more than 30 minutes. Facing different specifications and batches of fire cabinet orders, changeover losses are significant, and small batch orders have no cost advantage at all.

3. Prominent safety hazards and complex working environment

Workers need to be in close contact with bending molds and sheet metal. During manual material handling and positioning, hand crushing and scratching accidents are very likely to occur; bending thick plates requires multiple people to cooperate in handling, which is not only inefficient but also poses a risk of workpiece dropping.

Intelligent bending is a must-have for fire cabinet companies to upgrade.

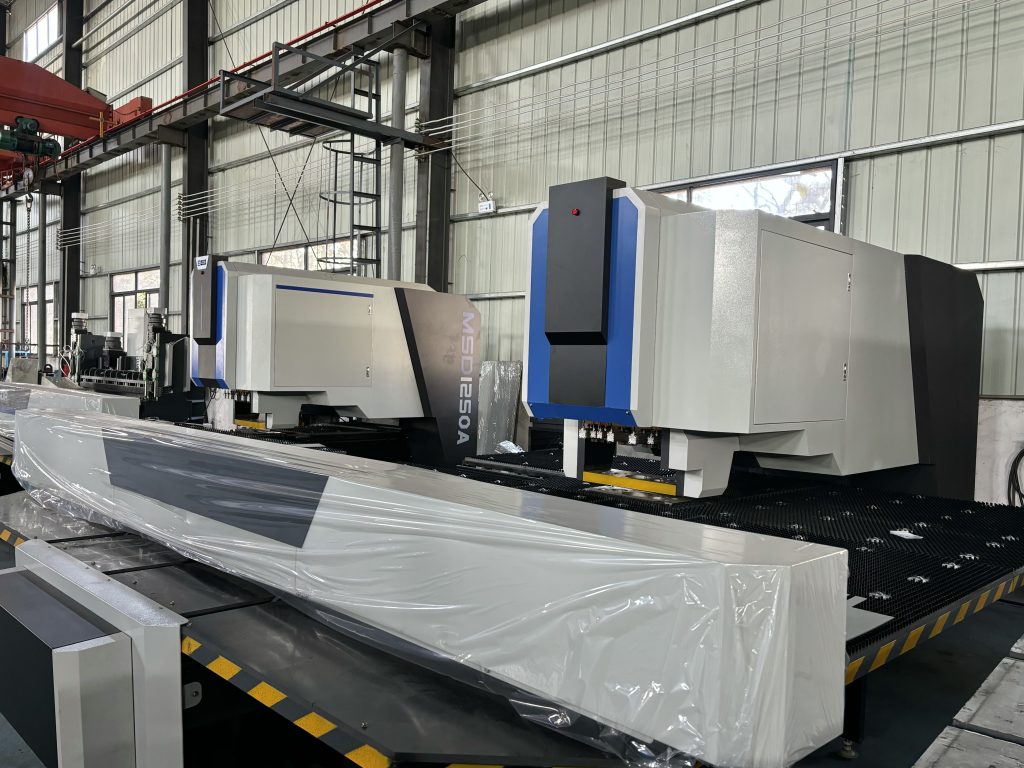

As emergency safety equipment, fire cabinets require both quality and efficiency. The Masda Intelligent Flexible Bending Center addresses the pain points of traditional processing, such as reliance on manual labor, insufficient precision, and low efficiency, achieving an “automated, high-precision, and flexible” upgrade for fire cabinet bending processing. This reduces overall costs and enhances product competitiveness.

RELATED NEWS