Masda CNC Punch Machine – Door Lock Pressing Process

I. The Origin and Technological Evolution of Door Lock Pressing

The door lock pressing process originated from the stamping forming needs in traditional lock manufacturing.

In the early days, it relied on manual punches and simple molds to complete the rough processing of the lock body structure.

With the popularization of smart door locks, the requirements for lock accuracy, strength and appearance have increased significantly, and traditional processes have gradually become difficult to meet the needs.

The introduction of CNC punches machine has promoted the innovation of door lock pressing technology. Through digital programming and precision molds, efficient forming of complex lock body structures has been achieved.

II. Application scenarios and sheet metal material adaptation

The door lock pressing process is widely used in the manufacturing of sheet metal parts for smart door locks, anti-theft door locks and industrial equipment locks. The core scenarios include:

1. Door lock pressing: using cold-rolled steel plates, aluminum alloys and stainless steel, etc., through pressing, precise structures such as door locks and sensor installation slots can be formed.

2. Lock body reinforcement ribs and connectors: The bridge-shaped structure is formed by stamping and stretching to improve the impact resistance of the lock, which is suitable for scenarios such as door locks and cabinet locks.

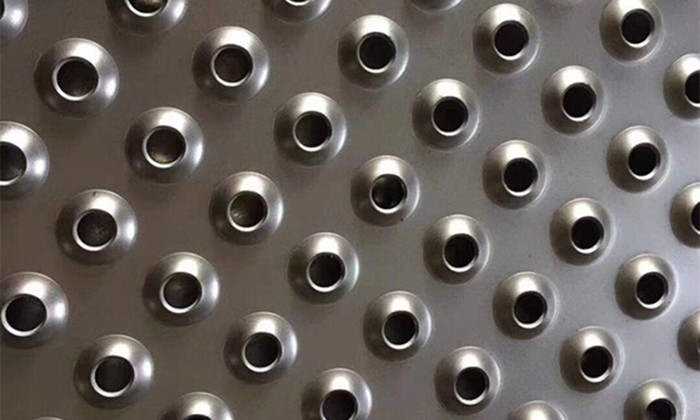

3. Decorative textures and heat dissipation holes: Using the multi-mold combination of CNC punching machines, non-slip patterns or heat dissipation shutters are embossed on the aluminum panel, which is both functional and aesthetic.

III. Core functions and technical advantages

The door lock profiling process achieves three core functions through CNC punching machines:

1. High-precision molding: The dimensional error can be controlled within ±0.1mm to meet the installation accuracy requirements of the lock body.

2. Structural reinforcement: Through U-shaped molds or step stamping technology, reinforcing ribs are formed on sheet metal parts to improve the lock body’s anti-bending ability and reduce the risk of deformation.

3. Efficient production: Supports batch processing and rapid mold change. Through Masda CNC punching machines, multiple processes such as punching, stretching, and embossing can be completed at one time, and production efficiency is increased by more than 50%.

V.Forming process and key technologies

The CNC punching process for door lock pressing includes the following key steps:

1. Mold design: Use high-speed steel molds to adapt to different lock body structures, such as shallow drawing molds, compound punching molds, etc., to ensure the balance between material ductility and precision during the stamping process.

2. CNC programming: Generate stamping paths based on software, preset punch pressure and pressing speed, optimize material utilization and reduce burrs.

3. Material pretreatment: High-hardness materials such as stainless steel need to be annealed to reduce the risk of stamping cracking; aluminum alloys require lubricants to reduce surface scratches

Process advantages of Masda CNC punching machine

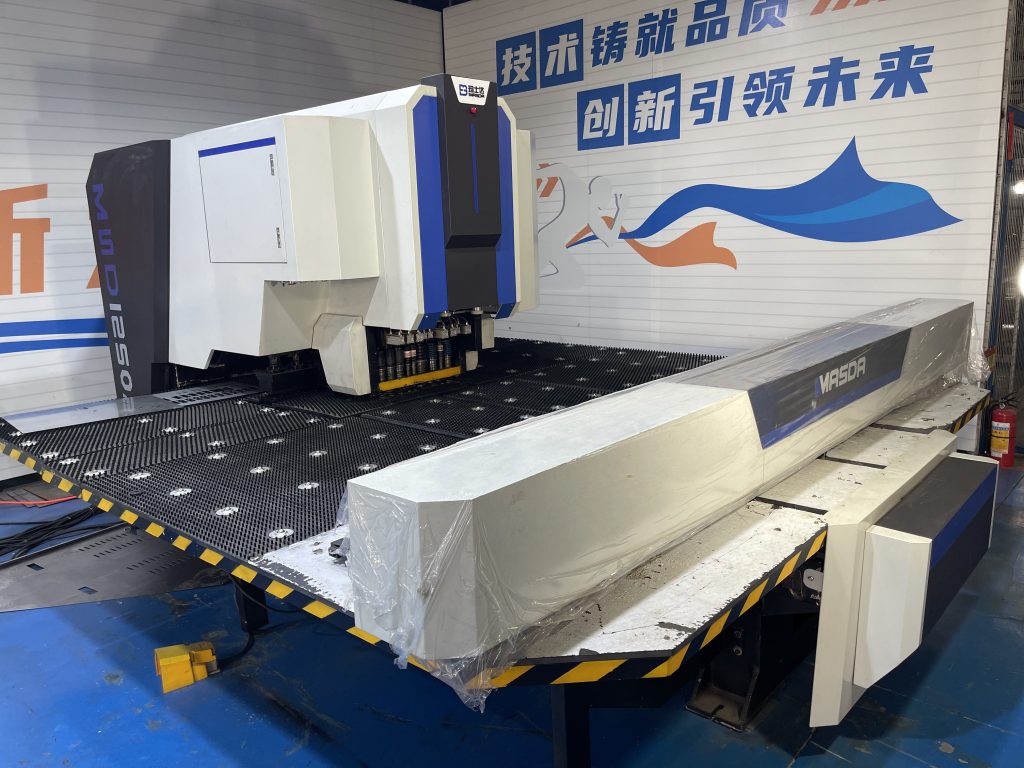

Masda CNC punching machine can stably process a variety of sheet metal materials, support rapid switching of modular molds, and adapt to the multi-specification requirements of door lock pressing.

The equipment is equipped with a CNC system, CAD drawings are imported for automatic typesetting and automatic recognition, and programming efficiency is increased by 30%, helping enterprises to achieve high-precision and low-cost large-scale production of locks.

RELATED NEWS