Masda Builds an Intelligent Sheet Metal Production Line for a Leading Electrolyzer Company

Achieving Unmanned Automated Processing Workshops

With 20 years of experience in the sheet metal equipment field, Masda has consistently empowered the sheet metal industry with customized solutions. Recently, its expertise earned the trust of a leading Chinese electrolyzer company, enabling them to build a dedicated sheet metal forming production line.

This client, a benchmark in China’s electrolyzer industry, ultimately chose Masda to customize their entire production line after multiple rounds of research and comparisons during the equipment selection phase.

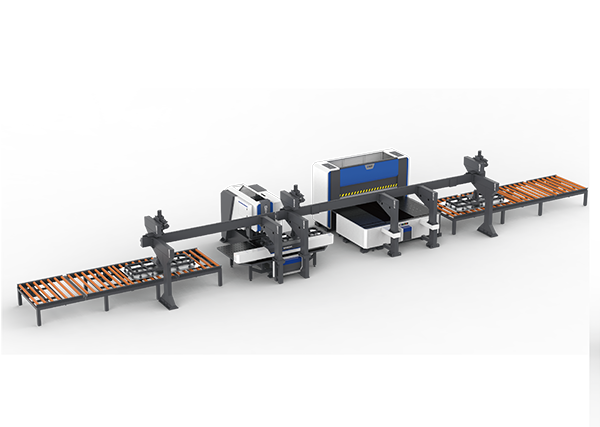

Considering the client’s processing materials, 2450x1300mm nickel and titanium plates, which are highly hard and large in size, requiring stringent processing precision and stability, Masda specifically configured a press brake and CNC punch press, along with three heavy-duty robotic arms, to create a fully automated production line.

The core advantage of this production line lies in its integrated system control—a single drawing is all that’s needed to drive the entire process, significantly reducing manual intervention errors.

It also incorporates Masda’s patented suction cup technology, leveraging large contact areas and powerful torque to achieve precise material feeding.

Its bending accuracy far exceeds industry standards, perfectly meeting the precision manufacturing requirements of electrolytic cell products.

Masda has been deeply engaged in sheet metal automation equipment for 20 years and now provides efficient sheet metal processing solutions to companies worldwide. Masda consistently meets customers’ diverse needs with one-stop service.

This collaboration with a leading Beijing electrolytic cell company is not only a testament to Masda’s technological strength, but also marks a breakthrough in the field of specialty material sheet metal processing.

In the future, Masda will continue to use its innovative equipment to help more companies reduce costs, increase efficiency, and achieve high-quality development.

RELATED NEWS