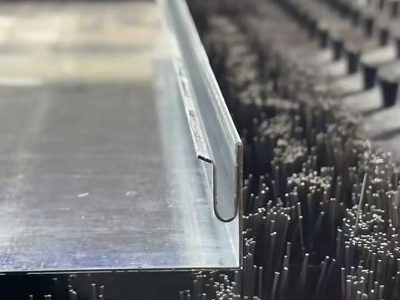

Masda Bending Machine – Roller Lashing Process

In the pursuit of efficient, aesthetically pleasing, and reliable sheet metal joining, the roller lashing process (also known as roll lapping) stands out with its unique advantages.

Originating in the mid-to-late 20th century, this technology has gradually matured with the surge in demand for precision sheet metal processing and the increasing demand for seamless connections, becoming a key process in modern manufacturing.

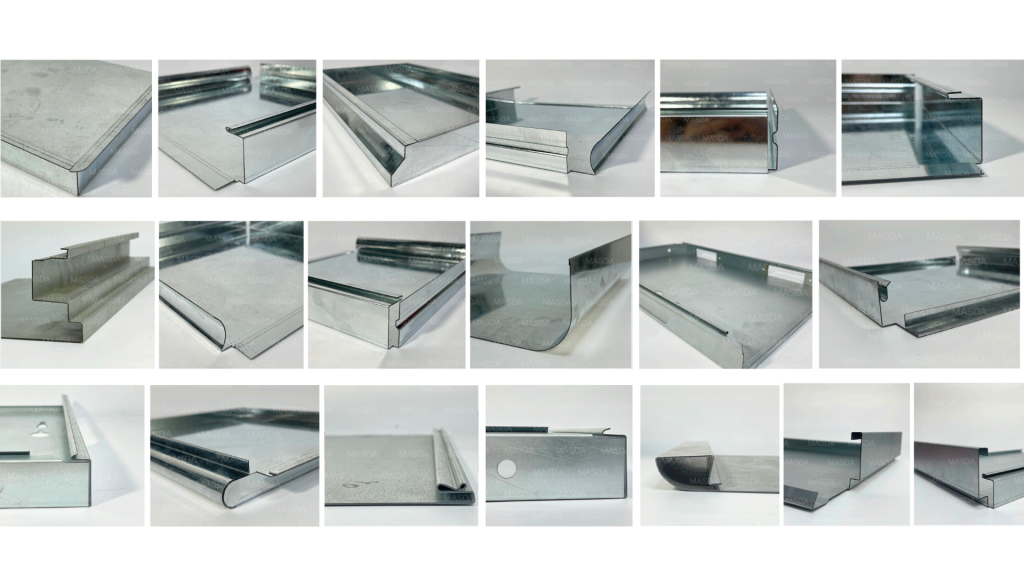

Wide Applications

The roller lashing process excels at processing a wide range of sheet metals, including:

• Stainless steel: Widely used in food processing machinery, medical devices, high-end kitchenware, and architectural decoration.

• Aluminum/aluminum alloy: Commonly used in electronic equipment housings, aerospace components, vehicle interiors, and curtain walls.

• Galvanized steel: Widely used in ventilation ducts (HVAC), electrical cabinets, building roof panels, and various chassis and cabinets.

Core Features and Benefits:

• Rivetless joining: Achieve a secure bond between sheets without drilling or using additional fasteners (such as rivets or screws).

• Smooth and aesthetically pleasing: The joint is smooth and flat, without protrusions, meeting the demands of products with high aesthetic requirements. • Good Sealing: The resulting continuous seam is airtight and liquid-tight, making it particularly suitable for piping systems.

• Reliable Strength: The interlocking structure achieved through plastic deformation of the material provides high joint strength and excellent vibration resistance.

• Efficient and Economical: Compared to traditional riveting, it is faster, requires fewer steps, and offers lower long-term costs.

Empowering Precision Sheet Metal Manufacturing

Masda’s intelligent press brakes, equipped with advanced CNC systems and high-precision roller buckle forming dies, provide a stable and efficient roller buckle process solution for sheet metal products such as ventilation ducts, chassis and cabinets, and high-end decorative products, helping you create seamless, strong, and beautiful sheet metal parts.

RELATED NEWS