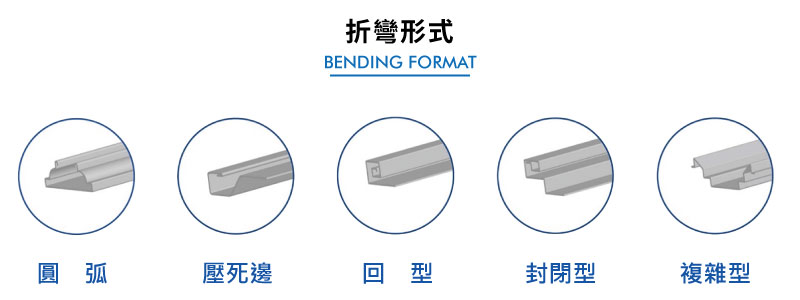

Masda Bending Machine – Back-Bending Process

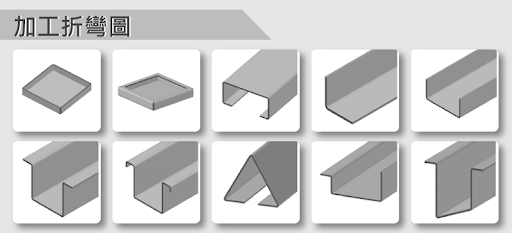

In sheet metal processing, back-bending is the key process for the bending machine to achieve a closed box structure.

Masda CNC bending machine can efficiently complete such complex forming with high-precision multi-axis positioning and intelligent program control.

The origin of the back-bending process

• Functional demand drive:

In order to meet the strict requirements of chassis, control cabinets, equipment housings, etc. for sealing, protection (dustproof/anti-electromagnetic interference) and structural strength, it is necessary to bend multi-sided sheet metal into a closed frame.

• Process evolution:

From early split welding to integrated bending and forming, the efficiency and overall rigidity are significantly improved, and the deformation risk caused by welds is reduced.

Application scenarios and typical materials

Core application areas:

• Electrical control cabinet: closed shell of PLC cabinet and distribution box.

• Industrial equipment cover: precision instrument protective cover, motor housing.

• Communication chassis: 5G base station equipment box, server housing.

• Medical equipment housing: testing instrument, surgical equipment protective box.

Thickness range: 0.8mm–3.0mm (over-thick materials require separate welding assistance).

Functional advantages

1. Structural integration: eliminate assembly gaps and improve overall rigidity and impact resistance.

2. Sealing and leakage prevention: seamless bending angles prevent liquid/dust intrusion (need to be combined with sealing strips).

3. Efficient production: CNC programmed operation, more than 50% more efficient than welding + assembly.

4. Beautiful and concise: no exposed screws or welds, stronger industrial aesthetics.

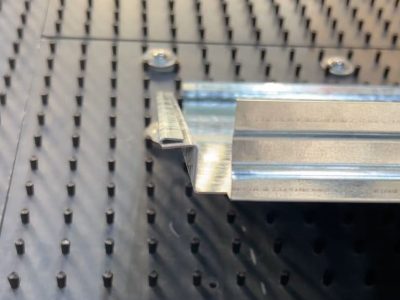

Process guarantee of Masda equipment

• Rebound compensation database: built-in material rebound parameters, automatic correction of bending angles.

• Tonnage adaptation: hydraulic system adjusts pressure in real time to prevent thin plates from being crushed or thick plates from being under-formed.

• Mold system: supports quick-change extended tools to meet the bending needs of large-size boxes.

Summary

The return process is the touchstone of high-end sheet metal box manufacturing-one-piece molding, zero welds, and extreme sealing.

With multi-axis positioning accuracy, intelligent program control and powerful tonnage output, Masda CNC bending machines provide high-yield closed structure solutions for carbon steel, stainless steel and aluminum plates, enabling the manufacturing of precision equipment in the fields of electrical, medical, and communications.