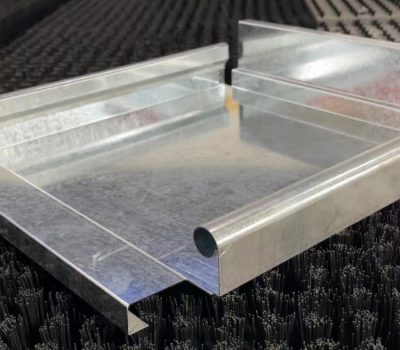

Masda Bending Machine – Arc Bending Process

In sheet metal processing, arc bending process beyond right angles gives the product an elegant streamline and unique functionality.

Masda CNC bending machine, with its high-precision control capability, makes complex large-radius arc forming efficient and accurate.

Origin of arc bending:

It stems from the improvement of sheet metal aesthetic design (such as arc shell, decorative edge) and functional requirements (such as reducing stress concentration, improving fluid guidance, and enhancing structural rigidity).

It is difficult to achieve accurate and consistent arcs by traditional manual or simple machinery.

The development of CNC bending technology, especially the maturity of segmented bending technology, makes efficient and accurate arc bending possible.

Application scenarios:

Arc bending process is widely used in fields that require smooth transitions and curved shapes:

Electrical housing: arc top cover or panel of refrigerators, air conditioners, and control cabinets.

Architectural decoration: metal cladding, arc curtain wall connectors, decorative lines.

Furniture and display racks: streamlined table edges, shelf arcs.

Industrial equipment: air deflectors, curved shields, hoppers.

Functional advantages:

Improve product aesthetics: Eliminate sharp edges and create a soft, modern visual effect.

Improve structural performance: Arc transition can effectively disperse stress, reduce the risk of cracking at the bend, and improve part strength and fatigue life.

Optimize functionality: Provide a smooth surface for easy cleaning, reduce resistance (such as fluid guidance), and improve user experience (such as no sharp edges).

Forming principle:

Arc bending is mainly achieved through step bending:

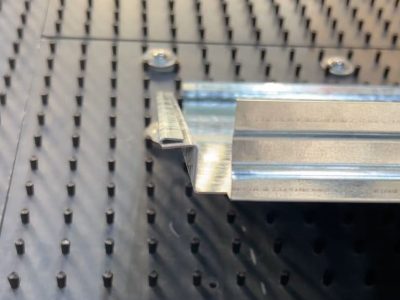

Programming and calculation: Engineers enter the radius (R) and arc length of the target arc in the Masda bending machine control system.

The system automatically calculates the required number of bending steps (number of bending lines), the bending angle of each step, and the precise movement of the back gauge (R axis).

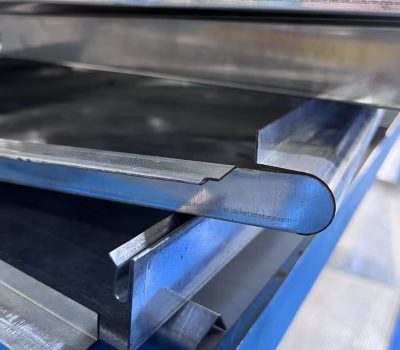

Mold selection: Use a sharp knife (small R angle upper mold) with a V-shaped lower mold of appropriate width. The R angle of the mold must be smaller than the target arc radius.

Precise positioning: The high-precision back gauge (R axis) of the Masda bending machine is responsible for accurately advancing the sheet to the next bending position after each bending.

Summary:

Masda CNC bending machines can simplify complex large-radius arc bending with high-precision motion control (especially the R axis) and strong rigidity, and efficiently realize the precision arc processing of materials such as carbon steel, stainless steel, and aluminum plates, helping you create more competitive sheet metal products.