Masda CNC Punching Machine-Typing Technology

I. Origin and Technological Development of Typing Technology

Typing technology originated from traditional stamping technology.With the development of CNC punching machines, its accuracy and efficiency have been significantly improved.

Modern CNC punching machines can accurately stamp letters, numbers or symbols on sheet metal materials through programming control to meet product identification and traceability needs.

II. Application scenarios and plate adaptation:

Widely used in electrical cabinets, chassis, mechanical equipment housings and other parts that require permanent identification.

Applicable materials include stainless steel, aluminum plates, cold-rolled plates, etc., with a thickness of usually 0.5-6mm,

especially suitable for parts that need to be uniformly marked in mass production.

Function:

Identity identification: Stamping product model, serial number, production date and other information for easy traceability and management.

Anti-tampering mark: Improve the durability of the mark by recessing characters to prevent human alteration.

III. Forming process:

Programming setting: Generate character outlines through CAD/CAM software and convert them into codes that can be recognized by CNC punching machines.

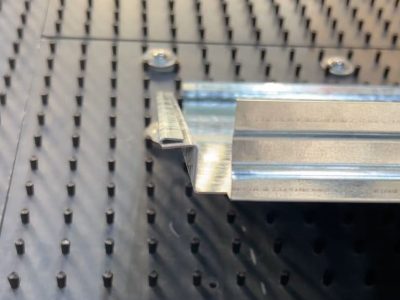

Mold selection: Use special character molds (such as punches and concave molds) to ensure font accuracy.

Stamping: After being positioned by the CNC system, the punch presses the sheet metal surface with high pressure to form recessed characters. The depth and font style can be adjusted according to needs.

Post-processing: Deburring the edges of the characters to ensure a smooth surface.

Technical advantages: High-precision positioning, character error ≤0.1mm; efficient batch processing, single-piece marking time ≤3 seconds; applicable to a variety of materials, compatible with different thicknesses and hardnesses.

RELATED NEWS