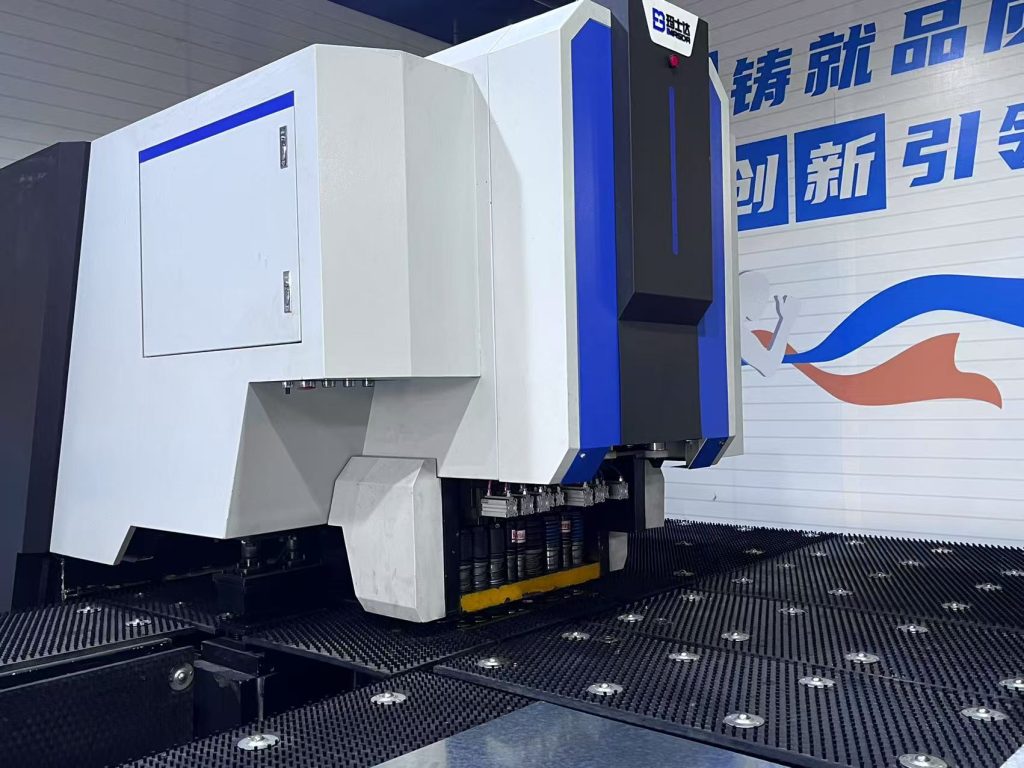

Masda CNC Punching Machine – Fisheye Hole Process

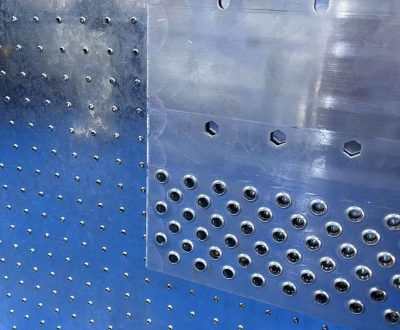

As a special punching hole type, fisheye hole process is named for its unique “fisheye” structure. In recent years, it has attracted much attention in the field of precision sheet metal processing.

Its process originates from the demand for electronic connector manufacturing, especially the processing requirements of high-density and small-pitch terminals in 5G communication equipment, which requires non-welding elastic connection, thus giving rise to high-precision fisheye hole forming technology.

I. The core function of fisheye hole

● Connection and fastening: Fisheye holes are often used for connection between parts.

Through bolts, rivets and other connectors through the fisheye hole, reliable fastening connection can be achieved to ensure the strength and stability of the connection part, such as in automobile manufacturing, building curtain walls and other fields.

● Fluid transmission and discharge: In some occasions where fluid circulation is required, such as the drum of a large washing machine, ventilation ducts, etc., fisheye holes can be used for fluid transmission, discharge or ventilation, and can also play a certain role in controlling the flow and direction of the fluid.

● Accurate positioning: Fisheye holes can provide precise positioning for the installation of parts and components, ensure the accurate position of each component during the assembly process, help improve the assembly accuracy and overall quality of the product, and are widely used in electronic equipment, medical equipment and other products with high precision requirements.

● Enhanced beauty: Fisheye holes have a unique shape and appearance.

Compared with ordinary round holes or holes of other shapes, they can add a certain degree of decorativeness to the product and enhance the overall aesthetics of the product.

They are often used as decorative holes in products such as furniture hardware and decorative hardware.

II. Application scenarios and material adaptability

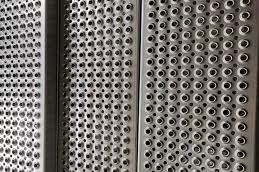

● Drum structure: Fisheye holes are often designed on the drum of large washing machines.

The function of these holes is to allow water to flow better inside and outside the drum during the washing process, so that the clothes can fully contact the water and detergent.

At the same time, during dehydration, they can effectively drain the water and improve the dehydration efficiency.

The shape and distribution of the fisheye holes are carefully designed to reduce the possibility of clothes being hooked or damaged by the edges of the holes during washing and dehydration.

● Building curtain wall: used to connect various components of the curtain wall, such as aluminum alloy profiles, glass, etc.

Fisheye holes can provide precise positioning and stable connection, making the curtain wall structure more solid, and its beautiful appearance can also enhance the overall visual effect of the curtain wall.

● Ventilation ducts: Fisheye holes are often used in the flange connection parts of ventilation ducts.

Using bolts or rivets to connect through fisheye holes can ensure the sealing and firmness of the pipe connection and ensure the normal operation of the ventilation system.

● Power equipment: There will be fisheye holes on the shell or internal structural parts of transformers, distribution cabinets, etc.

On the one hand, it is used to install internal electrical components to ensure the accuracy and stability of component installation; on the other hand, it is used for the assembly of the shell to make the equipment shell more solid, and it is also convenient for heat dissipation and wiring.

● Medical equipment: On the shell, bracket or parts of some medical devices, fisheye holes can be used to install various sensors, display screens, operation buttons, etc., and can also be used for the assembly and fixation of equipment to ensure the accuracy and reliability of medical devices.

● Fitness equipment: For example, the frame of a treadmill, dumbbell rack and other parts, fisheye holes can be used to connect different rods or install accessories to make the structure of fitness equipment stable and meet the strength requirements of users during use

III. Key technologies of fisheye hole forming process

The forming of fisheye holes depends on high-precision CNC punching machines and special mold design. The core processes include:

1. Staged stamping: avoid burrs and material deformation through multi-station synchronous processing such as avoidance hole punching, partial puncture, and waste removal.

For example, pre-forming with a semi-punching process (punching into the material 40% depth) and then complete punching can reduce collapse angles and improve side finish.

2. Stamping forming

● Principle: Use the punch and mold of the CNC punching machine to apply pressure to the sheet, so that the sheet undergoes plastic deformation under the action of the mold, thereby forming a fisheye hole.

● Features: high production efficiency, suitable for mass production; good hole size accuracy and shape consistency;

IV. Process advantages and future trends

The Masda fisheye hole process significantly reduces production costs due to its high efficiency stamping and no additional surface treatment.

With the popularization of 5G and new energy vehicles, their demand will continue to grow, promoting the development of intelligent molds (such as multi-process integration of progressive dies) and lightweight materials.