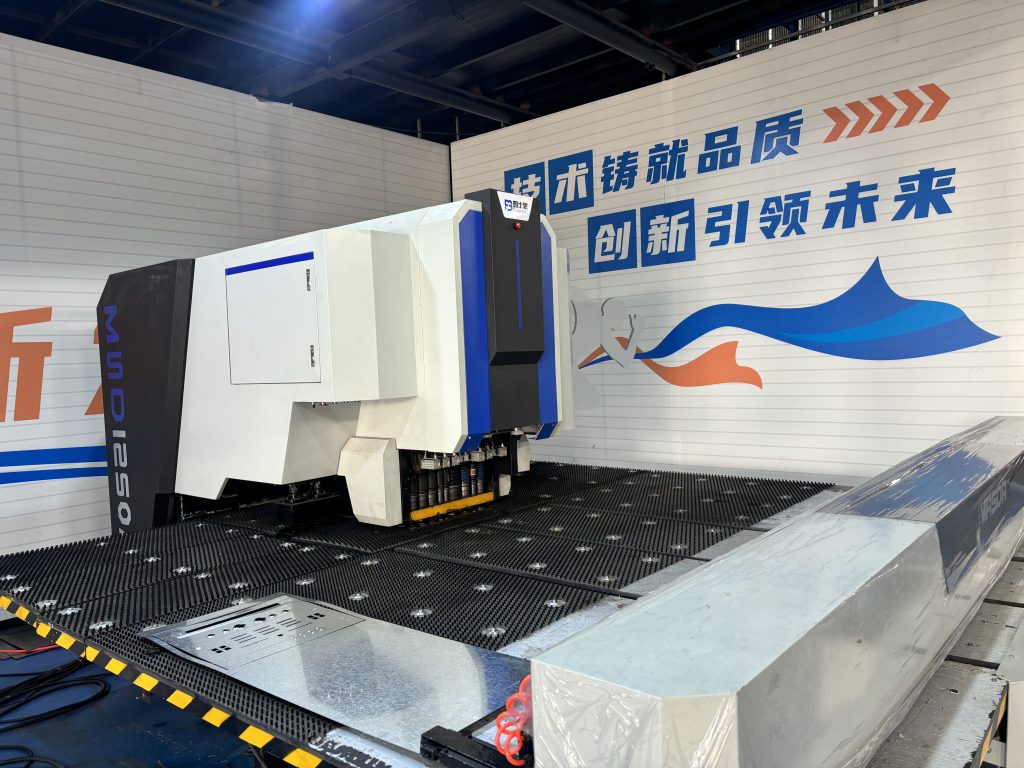

Masda CNC Punching Machine – Venetian Blinds Process

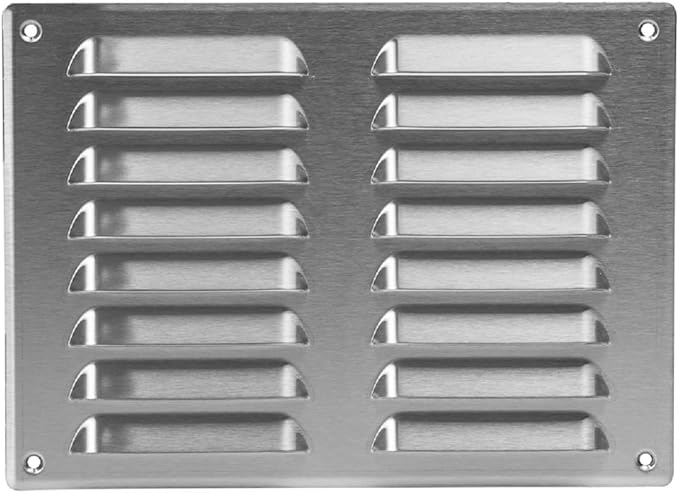

一.、The Origin and Function of Venetian Blinds

Venetian blinds can be traced back to the wooden window lattice structure in ancient China, and later improved in Europe to become a practical design that combines sunshade and ventilation.

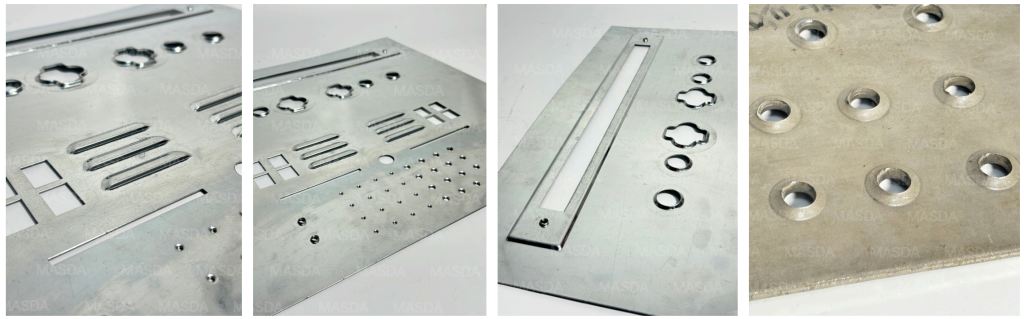

In the field of sheet metal processing, the venetian blinds process is formed by stamping metal sheets, which is both functional and decorative. The main functions include:

1. Ventilation and heat dissipation: air circulation is achieved through the gap between the blades, and it is widely used in chassis, electrical cabinets and other equipment.

2. Dust and foreign matter prevention: The inclined blade design can prevent dust or debris from entering the equipment, improving product reliability.

3. Lightweight and beautiful: Compared with the traditional open hole structure, the venetian blinds can reduce weight through stamping and give the product a modern industrial aesthetic.

二、 Application scenarios and sheet metal material selection

The venetian blinds process process is widely used in sheet metal manufacturing, and the main scenarios include:

1. Industrial equipment: such as communication cabinets, power control boxes, etc., which need to take into account heat dissipation and protection. Commonly used materials are cold-rolled steel plates, galvanized plates and aluminum alloy plates, with a thickness range of 0.5-3.0mm.

2. Architectural decoration: such as metal curtain walls and ventilation partitions, mostly use weather-resistant colored aluminum or stainless steel materials, and the surface can be sprayed or brushed to improve the appearance.

3. Automobile and transportation: used for body vents or interior parts, which need to meet high strength and lightweight requirements, and often use high-tensile steel plates or aluminum-magnesium alloys.

三、 Forming process and technical advantages

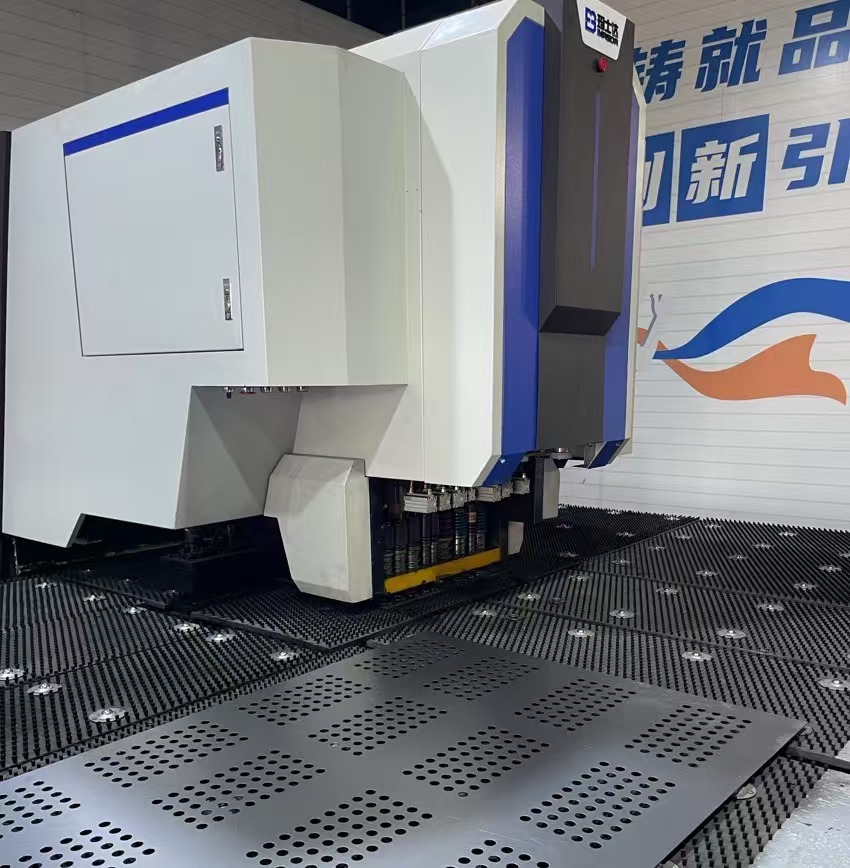

The forming of modern sheet metal shutters mainly relies on CNC punching (NC) technology, and its core steps include:

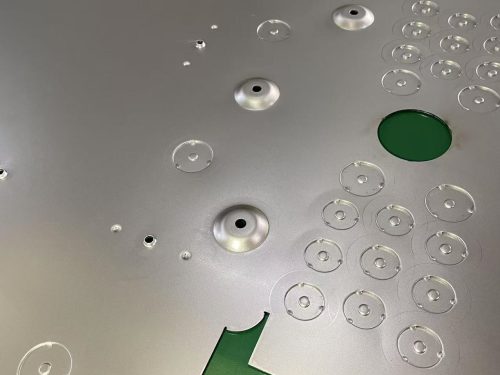

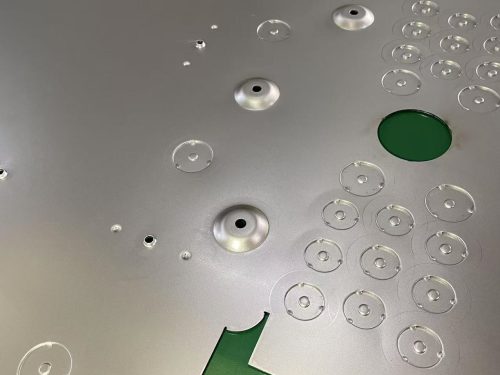

1. Mold design: A U-shaped blade punch and a punch lower die are used to complete the blade forming through one stamping, without the need for secondary folding, which significantly improves efficiency.

2. CNC programming: Set the punching path according to parameters such as blade spacing and angle, support mass production and customized processing, and the dimensional accuracy can reach ±0.1mm.

3. Material adaptability: Masda CNC punch press can process stainless steel 3mm, iron plate 5mm, aluminum plate 6mm, and avoid burrs or cracks by adjusting the mold gap (1.15-1.3 times the thickness of the plate).

The breakthrough in the CNC punch shutter process not only continues the practical aesthetics of the traditional structure, but also expands its application in high-performance equipment and green buildings through intelligent manufacturing technology.

Among them, CNC punch presses are one of the core technologies of sheet metal processing.

Their high efficiency and precision characteristics promote the transformation of the sheet metal industry from traditional manual operation to intelligent and digital production.

RELATED NEWS