Masda sheet metal intelligent manufacturing unmanned production line: an automation revolution of efficiency and precision

Full-process intelligent collaboration redefines sheet metal manufacturing

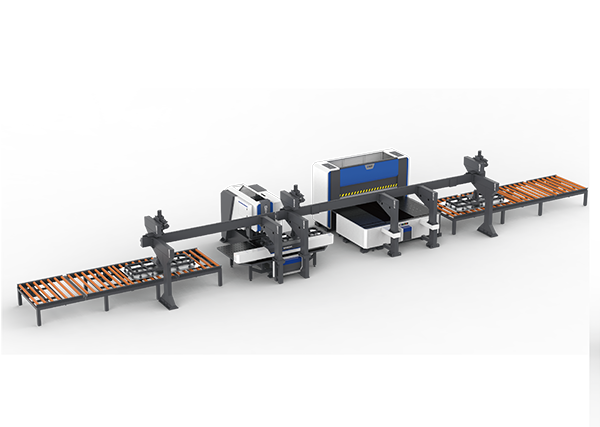

In the wave of industrial intelligence, Masda launched a sheet metal intelligent manufacturing unmanned production line, with a robotic arm as the core drive, to create an efficient production closed loop of “unmanned + digitalization”.

From sheet loading to finished product off-line, the production line uses the robotic arm to accurately connect key links such as CNC punching machines (digital punching, hydraulic, tapping), bending centers (bending, edge beating, arc forming), etc., to achieve 24-hour collaborative operation of the entire process.

This innovative model not only subverts the inefficient pain points of traditional manual operations, but also sets a new benchmark for the sheet metal industry with stable and precise digital control.

Four core advantages, interpreting the hard power of intelligent manufacturing

1. Efficiency leap: The robotic arm operates 7×24 hours without interruption, and with the intelligent production scheduling system, the production efficiency is 3 times higher than that of traditional production lines, and the single product cycle is shortened to 1/2 of the traditional process.

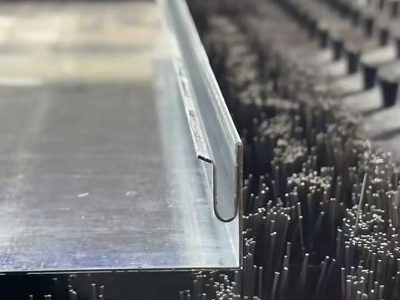

2. Quality Revolution: The digital system monitors parameters such as stamping depth and bending angle in real time, automatically compensates for errors, and the product yield rate is stable at 99.8%, completely saying goodbye to the unstable factors of manual operation.

3. Flexible production: The modular design supports rapid changeover of products with multiple specifications to meet the diverse needs of customers.

4. Safety upgrade: The robot arm obstacle avoidance system achieves “zero accident” production. At the same time, the cloud platform traces the process data throughout the process to provide transparent support for quality control.

Empowering the future of manufacturing with the power of intelligent manufacturing

The unmanned production line of sheet metal intelligent manufacturing of Masda is not only a manifestation of technical strength, but also a precise response to the pain points of the industry.

By reducing manual intervention and reducing comprehensive costs by more than 30%, while improving production capacity and quality, the production line has been successfully applied to multiple fields such as door industry, kitchen cabinets, and fire protection facilities, helping customers achieve cost reduction, efficiency improvement, and market competitiveness leap.

As a pioneer in the era of Industry 4.0, Masda is promoting the transformation of sheet metal manufacturing to intelligence and high-end with unmanned production lines as the core.

Choosing Masda is not only choosing a production line, but also choosing a more efficient, safer and future-oriented manufacturing ecosystem.

RELATED NEWS